(1) Sample storage process

1. Submit an application. Before storing samples, an application must be submitted to the person in charge of the biological sample library and the Sample Storage Application Form must be filled out. If the samples are widely stored, the clinical departments generally apply to the biobank. If the samples are supported by the project, the project leader should submit an application to the biobank and suggest that the research project plan be provided at the same time.

2. Evaluation and review. The biobank evaluates the projects and samples, mainly investigating the project level, scientific research value, treasure degree of the samples, whether they meet the ethical requirements, etc. Only after approval can the storage procedures be further processed.

3. Submit a sample collection plan. After approval, a detailed sample collection plan should be submitted to the biobank, specifying the requirements and operation methods of important processes such as sample collection, transportation, processing and handover.

4. Sign a storage agreement. Before the samples are formally transported to the biobank, both parties need to sign the Agreement on Sample Storage, negotiate and confirm the signing of informed consent and specific implementation methods for the implementation of the sample collection plan, and receive blank informed consent and storage consumables as required.

5. Samples and information are stored. When the samples are sent to the biobank, both parties should check the important information such as sample type and quantity, and fill in the Sample Transfer Form.

(2) Instrument and equipment

1. Gas phase liquid nitrogen tank

This center adopts the German TANKA Biosystem series liquid nitrogen tanks to provide a safe and reliable deep low-temperature storage environment for biological samples. Advanced vacuum extraction technology and high vacuum lasting maintenance technology minimize the evaporation loss of liquid nitrogen. The tank is equipped with a device to prevent the flow of liquid nitrogen, which can control the liquid nitrogen in a safe annular space and keep the entire storage space in a constant gas-phase liquid nitrogen environment.

2. Water cooled ultra-low temperature refrigerator

This center adopts a water-cooled ultra-low temperature refrigerator from GFL in Germany. The advantages of using a water-cooled ultra-low temperature refrigerator to store samples are as follows: 1. The water cooling system replaces the traditional wind cooling system, allowing the heat generated during the operation of the refrigerator to be dissipated outdoors by the water cooling system, improving heat dissipation efficiency, avoiding indoor temperature rise, keeping the refrigerator compressor at a suitable working temperature, shortening the time required for refrigeration, and extending the lifespan of the refrigerator. In addition, GFL refrigerators use pure hydrocarbon natural coolants for cooling, which do not release Freons that cause ozone layer damage during use, making them truly environmentally friendly refrigerators.

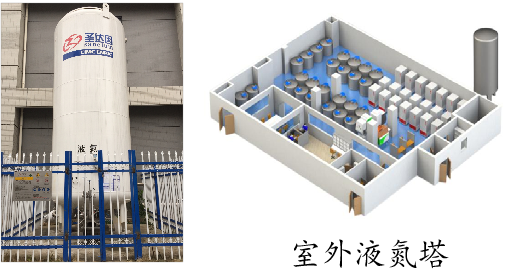

3. Large liquid nitrogen tower and liquid nitrogen pipeline

This center has the only outdoor liquid nitrogen tower dedicated to biological sample storage in central China. The liquid nitrogen tower adopts a unique internal insulation structure design and advanced vacuum pumping technology, which can provide continuous liquid nitrogen supply to the entire liquid nitrogen pipeline system, liquid nitrogen tank and automatic gas phase storage system of the sample library. The liquid nitrogen pipeline adopts a double-layer vacuum insulated metal pipe structure design, and corresponding liquid level solenoid valves are installed at the intersection and end of the pipeline. Through the main solenoid valve box, the flow of liquid nitrogen inside the pipeline can be monitored in real time, maintaining normal pressure inside the pipeline and allowing gas to be discharged from the warehouse through the pipeline in a timely manner.

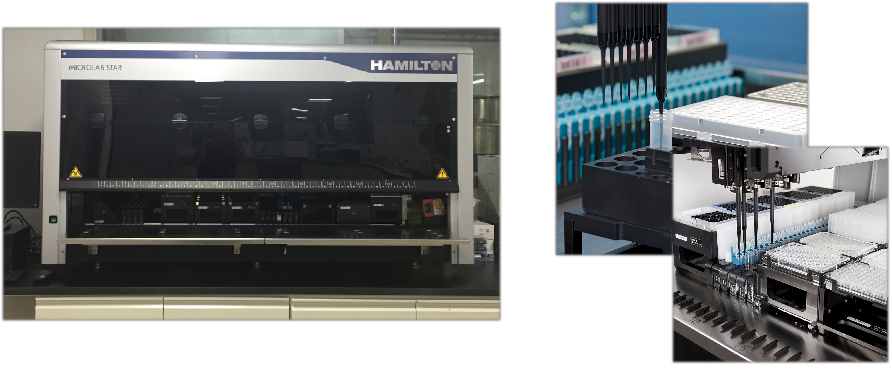

4. Liquid workstation

The Microlab STAR series automated liquid workstation can automatically identify and package different components of blood samples. The liquid workstation is controlled by software, uses air displacement and a unique CO-RE system for robust performance to maximize sample integrity. The use of liquid workstations shortens the pre-processing time of blood samples, improves sample quality, not only improves processing efficiency, but also avoids the possibility of manual error.

5. Program cryogenic cooling instrument

The German ASKION Work Bench program cryogenic thermometer can be used for programmed cooling and low temperature packaging of a variety of biological samples such as cells and blood. The Work Bench is composed of a cooling zone and a low temperature operation zone. The cooling zone is used for programmed cooling of samples, and the operation zone is used for packaging, sorting, and other operations of cooled samplesat -100℃. The Work Bench performs programmed cooling through the preset frozen storage curve, and the precise temperature sensor can ensure that the actual cooling curve of the sample is consistent with the height of the set cooling curve. Also, it can be equipped with 2-3 sample lifting platforms, which are independent of each other. The operation of one lifting table does not affect the operation of other lifting platforms, allowing users to simultaneously program cooling of samples with different cooling rates.

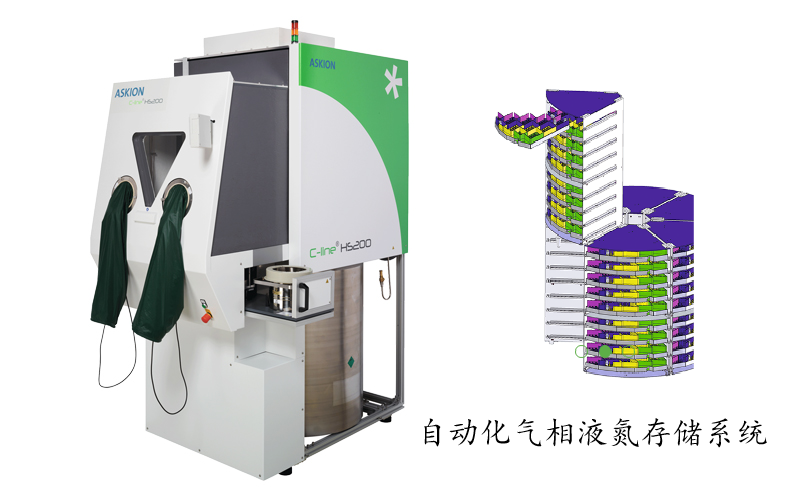

6. Automatic gas-phase liquid nitrogen storage system

The most important feature of the fully automated gas-phase liquid nitrogen storage system (C-line System) is its ability to maintain the temperature of the sample between -140 ℃ and -196 ℃, enabling fully automated operations. During the process of storing or retrieving samples, the samples are automatically lifted and dropped by mechanical devices, and the access operation of the samples is completed by an automated robotic arm in a low-temperature operating zone of -130 ℃. At the same time, the system can record all the information of the sample in real time, including storage location, temperature records, historical operation information, etc., ro ensure 100% traceability of the sample information. The C-line System can also monitor the status of the system in real time, once the problem occurs, the sound and light alarm is immediately issued, and the remote monitoring can be realized through the external remote alarm equipment.

(3) Storage scheme

To avoid the potential loss of samples caused by uncontrollable factors such as natural disasters, all samples stored in the biobank are stored separately in different locations when there are sufficient copies. Each sample is numbered according to certain rules, and each sample has an exact record corresponding to the actual location.